New Technologies In Mechanical Engineering

Mechanical engineering is one of the oldest and most important engineering disciplines. For centuries, mechanical engineers have been developing new technologies that make our lives easier, more efficient and more comfortable. In recent years, new technologies in mechanical engineering have developed particularly rapidly. These new technologies have the potential to fundamentally change the way we live and work.

Here are some of the most important new technologies in mechanical engineering:

Artificial Intelligence (AI)

AI systems can learn and adapt to new situations. They can also take on tasks that were previously done by humans, such as quality assurance or diagnosing machine errors. AI systems are being used in more and more machines and systems, and they will become even more important in the future.

Here are some examples of the use of AI in mechanical engineering:

- In quality assurance, AI systems are used to inspect products and components for defects.

- In the diagnosis of machine faults, AI systems are used to identify the causes of machine failures.

- In the control of machines and plants, AI systems are used to make processes more efficient and accurate.

Virtual Reality (VR) and Augmented Reality (AR)

VR systems allow users to be immersed in a virtual environment. AR systems project digital information into the real world. VR and AR systems are used in education and training. They are also used in other areas, such as marketing and sales.

Some examples of the use of VR and AR systems in mechanical engineering:

- In education and training, VR systems are used to train users on machines and systems.

- In marketing and sales, VR and AR systems are used to present products and services.

- In research and development, VR and AR systems are used to develop new products and processes.

In component manufacturing, additive manufacturing processes are used to create components that are lighter and stronger than components manufactured using conventional processes.

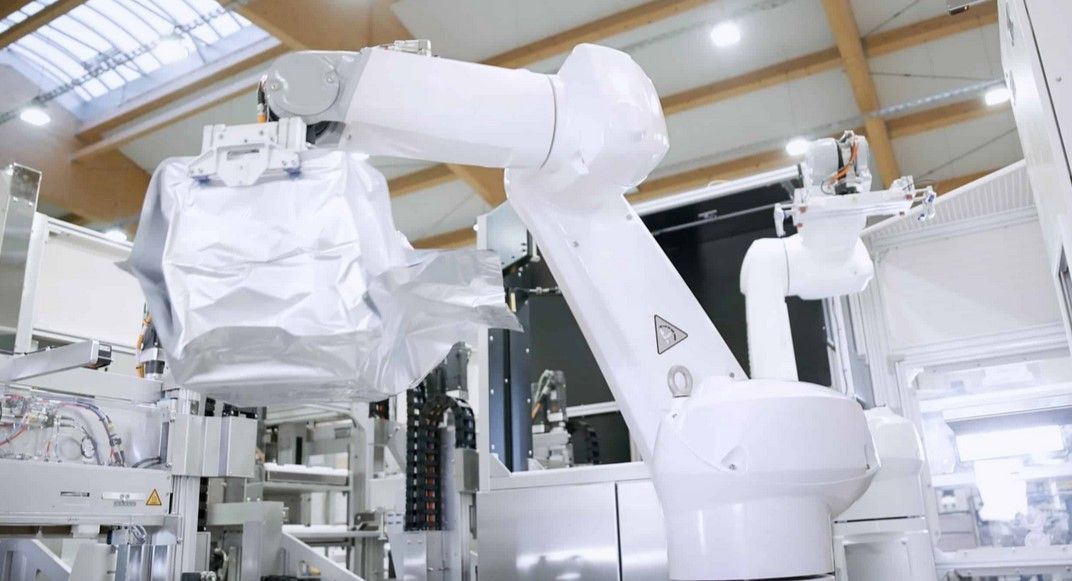

Robotics

Robots can take on tasks that are too dangerous or strenuous for humans. They can also perform tasks that require a high degree of precision or speed. Robots are being used more and more in production, and they will become even more important in the future.

Here are some examples of the use of robots in mechanical engineering:

- In the assembly of components, robots are used to quickly and accurately assemble the parts.

- In the painting of workpieces, robots are used to paint the workpieces evenly and flawlessly.

- In the inspection of products, robots are used to inspect products for defects.

Industry 4.0

Industry 4.0 is a concept that describes the networking of machines and systems in production. Industry 4.0 makes it possible to design production processes more efficiently and flexibly and is the most important trend.

Some examples of the application of Industry 4.0:

- The networking of machines and systems makes it possible to collect and evaluate production data.

- The evaluation of production data makes it possible to optimize production processes and improve product quality.

- The networking of machines and systems makes it possible to develop new products and processes.

Additive manufacturing processes are used in component manufacturing to create components that are lighter and stronger than components manufactured using conventional processes.

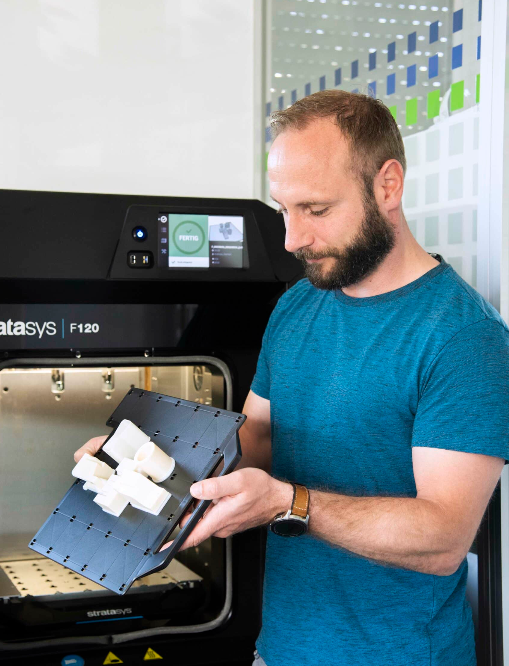

Additive manufacturing

Additive manufacturing is a process in which three-dimensional objects are built up layer by layer from a liquid or powdery material. Additive manufacturing is used in the production of prototypes, tools and components. Additive manufacturing makes it possible to produce parts that cannot be made using conventional methods.

Some examples of the use of additive manufacturing in mechanical engineering:

- In the production of prototypes, additive manufacturing processes are used to create prototypes quickly and cost-effectively.

- In the production of tools, additive manufacturing processes are used to create tools that are needed to process complex workpieces.

- In component production, additive manufacturing processes are used to create components that are lighter and stronger than components produced using conventional methods.

Advantages and challenges

Advantages

- Increased efficiency: The efficiency of production processes can improve. This leads to cost savings and higher productivity.

- Quality improvement: The quality of products can also improve. This leads to more satisfied customers and higher customer loyalty.

- Innovation: The development of new products and processes offers a competitive advantage and can help achieve greater market penetration.

Challanges

- Cost: New technologies can be expensive. This may require an investment in research and development, employee training, and the purchase of new machinery.

- Risks: Job losses, security risks, and data protection violations are possible.

- Acceptance: New technologies must be accepted by employees and customers. This can be a challenge if the technologies are complex or novel.

- Regulation: Authorities may regulate the use of new technologies, which can cause delays or make their use more difficult.

- Complexity: New technologies can be complex. This can require the training of employees and make machine maintenance more difficult.

Overall, new technologies in mechanical engineering offer many advantages. However, there are also some challenges to consider. The mechanical engineering industry faces an exciting future in which new technologies are developing faster and faster.

Unternehmen | About cts

Kontakt | Contact

Karriere | Career

Impressum | Imprint

Datenschutz | Privacy

AGB | GTC

Blog | News

Presse | Press

Glossar | Glossary

cts GmbH competence for technical solutions

Fuhrmannstraße 10

84508 Burgkirchen a.d. Alz

All rights reserved cts GmbH 2025 ©